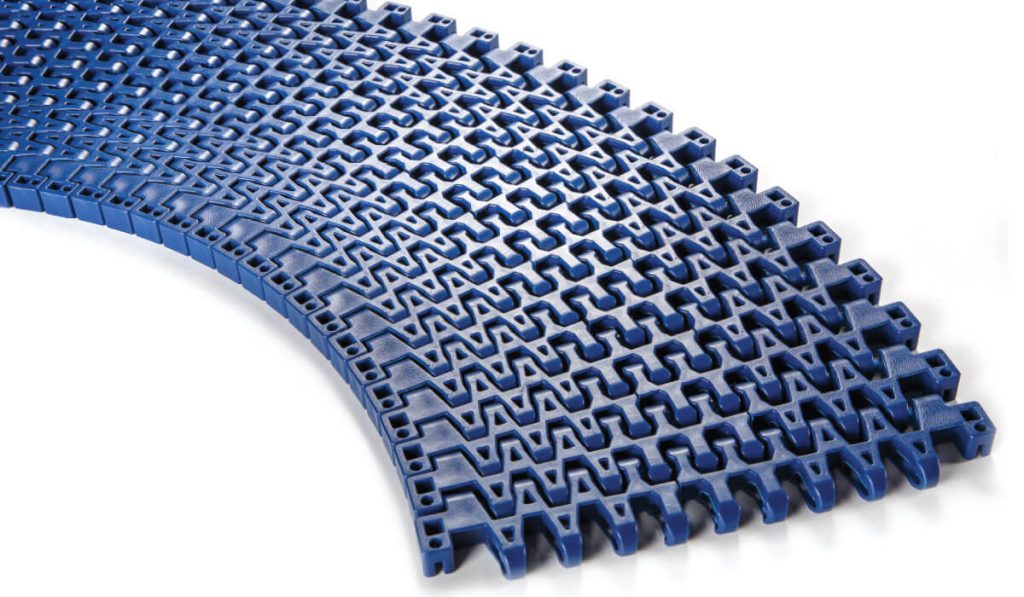

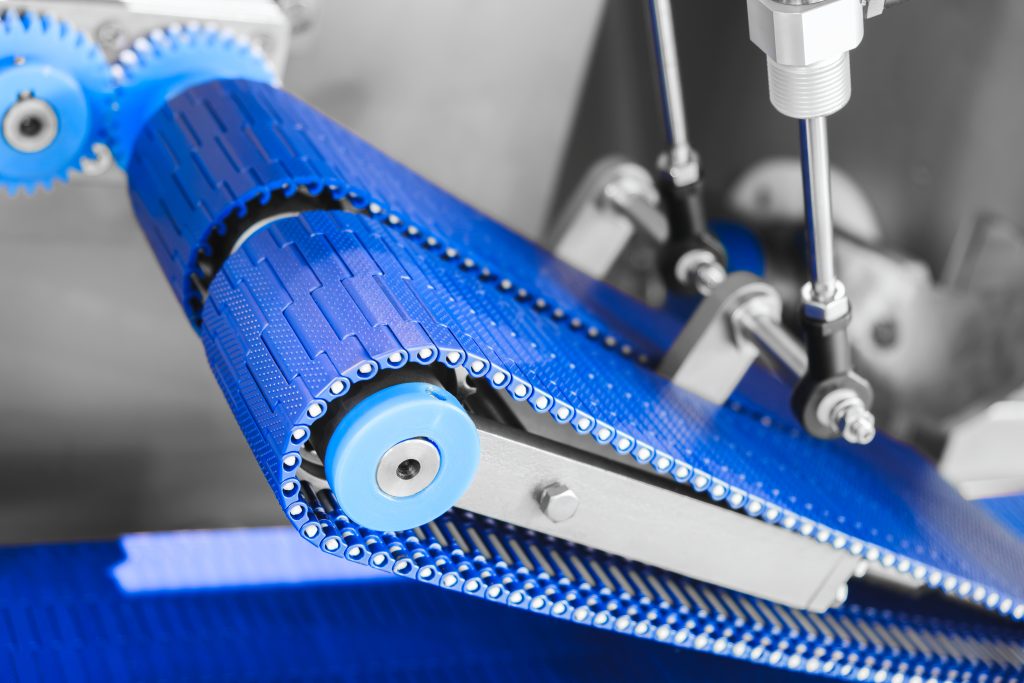

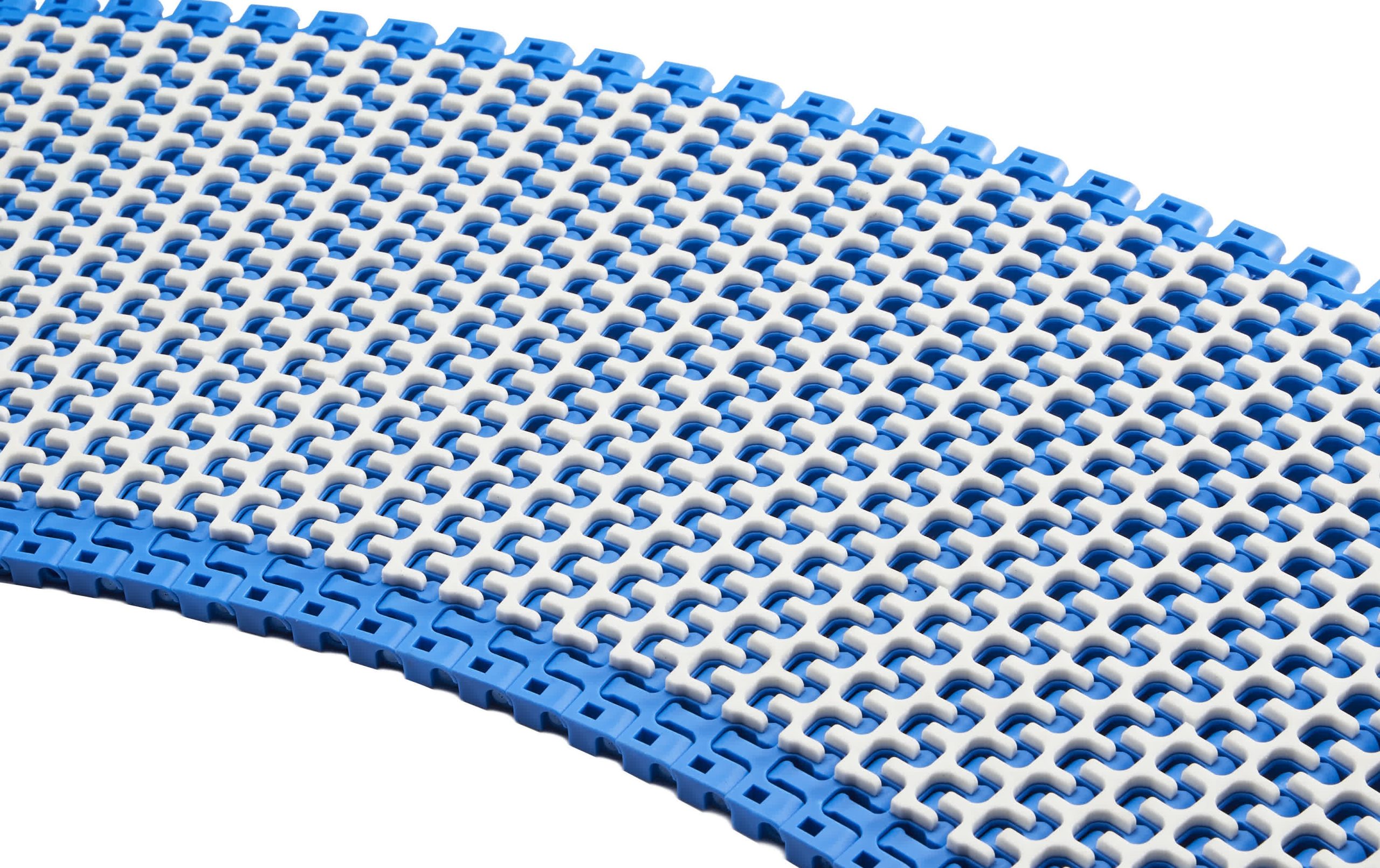

Modular belts are conveyor belts consisting of individual plastic modules connected to each other by rods. This design provides flexibility, strength and ease of replacement of individual elements in case of wear or damage.

Fill out the feedback form to get expert advice, learn more about our products, or discuss your project.

Our team will contact you shortly to answer your questions and offer the best solution.