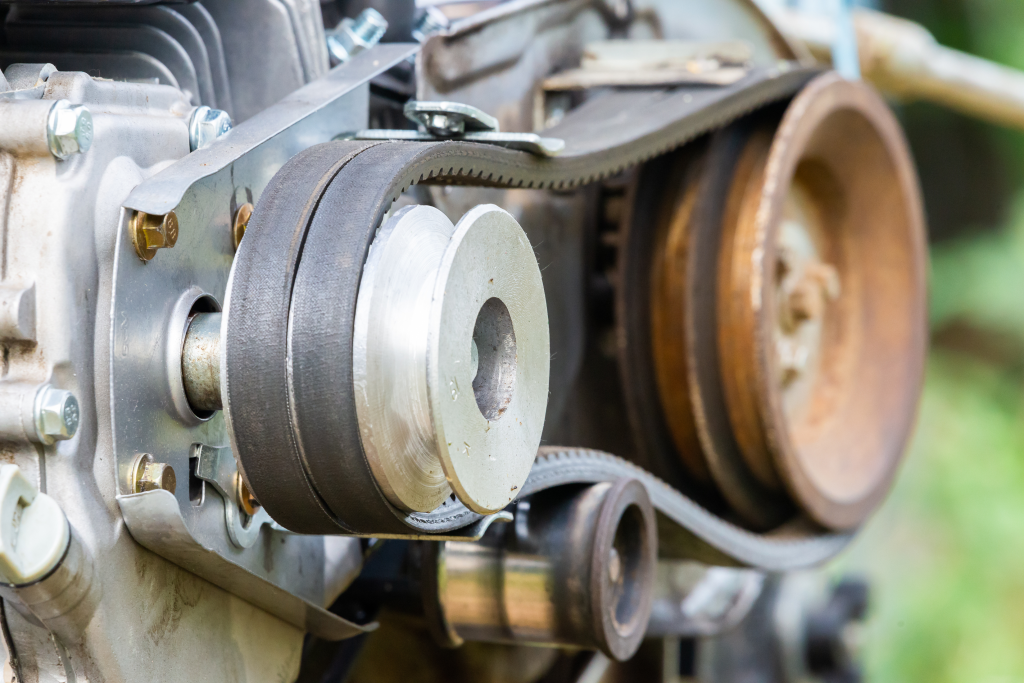

V-belts are trapezoidal section drive belts designed to transmit torque between pulleys. They provide high traction due to friction of the side surfaces and are suitable for use under heavy loads. V-belts are durable, wear-resistant and easy to install. They are used in cars, agricultural and industrial machinery.

Fill out the feedback form to get expert advice, learn more about our products, or discuss your project.

Our team will contact you shortly to answer your questions and offer the best solution.