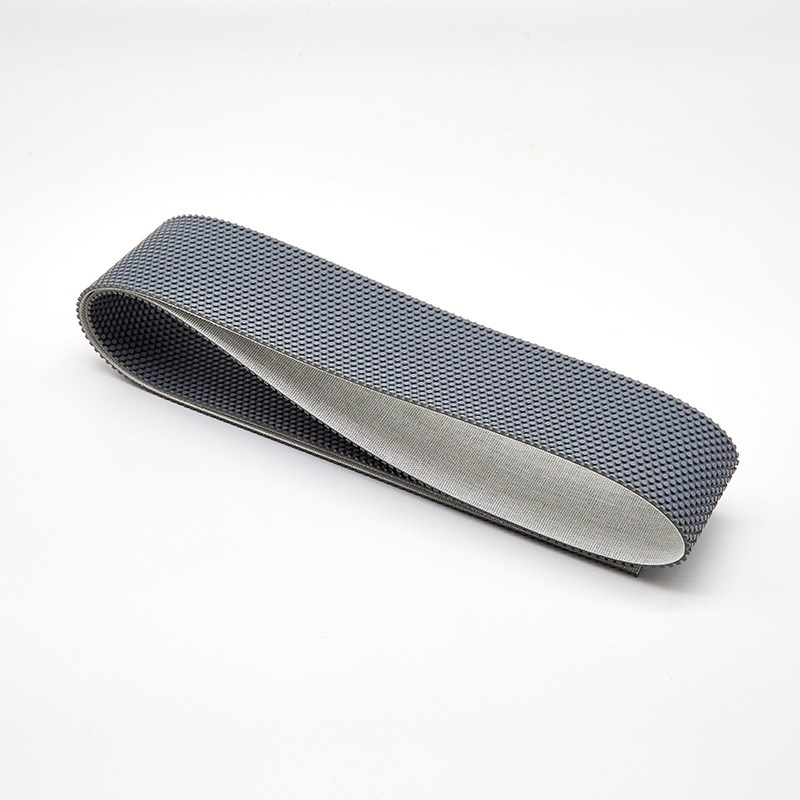

Roller coverings are special materials applied to the surface of shafts to improve their performance. They perform various functions: prevent wear, improve adhesion, reduce friction, or protect the shaft from corrosion and damage.

Fill out the feedback form to get expert advice, learn more about our products, or discuss your project.

Our team will contact you shortly to answer your questions and offer the best solution.