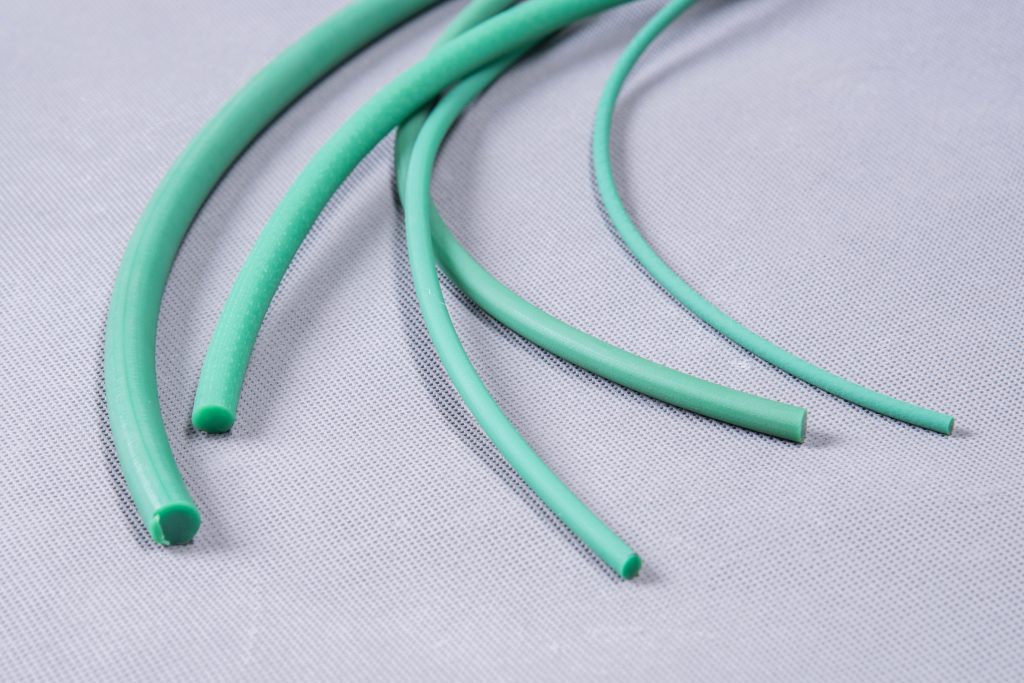

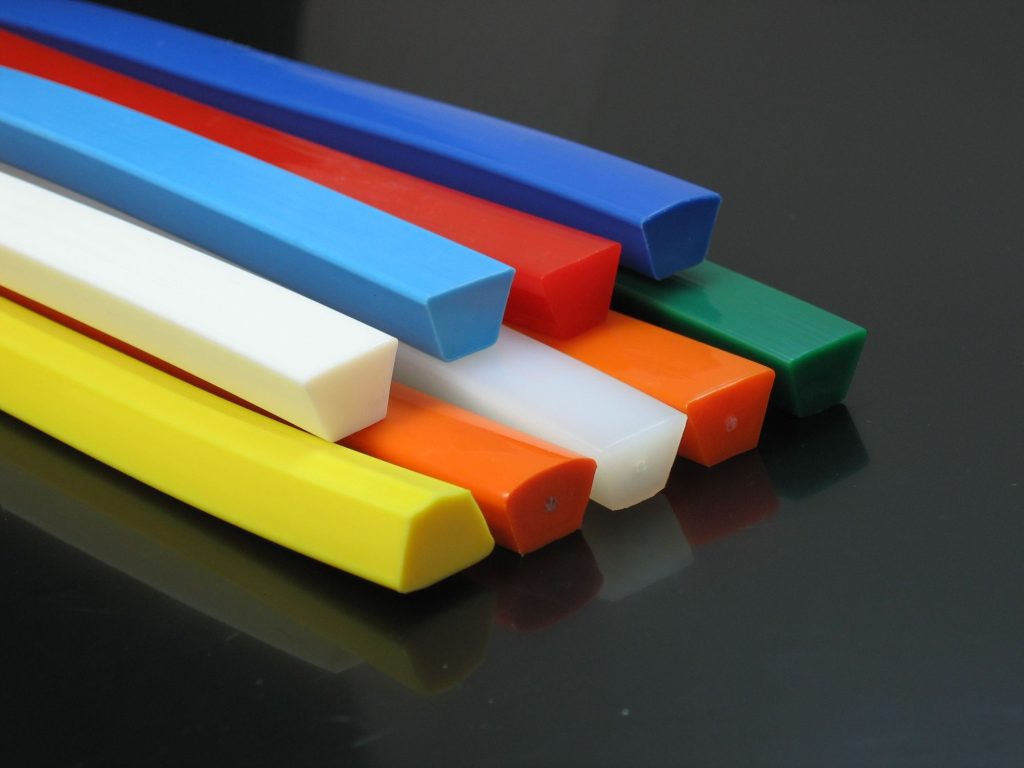

Thermoweldable belts are drive and conveyor belts made from thermoplastic materials such as polyurethane or PVC, joined using heat welding. This seamless connection ensures high durability, reliability, and resistance to wear. These belts are ideal for applications requiring smooth operation, hygienic properties, and strong mechanical performance.

Fill out the feedback form to get expert advice, learn more about our products, or discuss your project.

Our team will contact you shortly to answer your questions and offer the best solution.