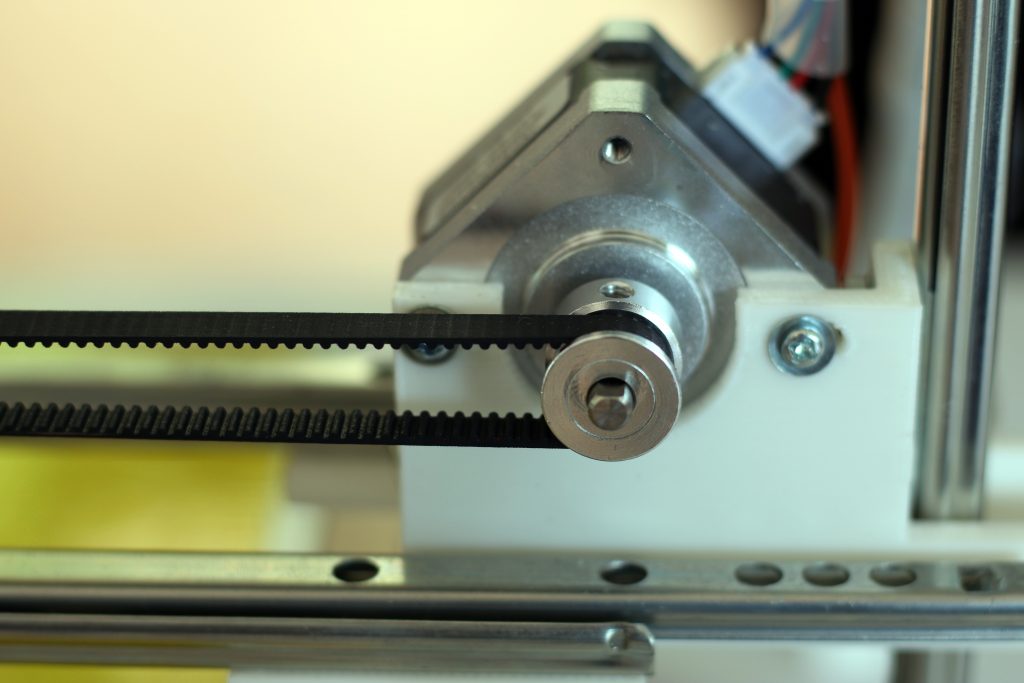

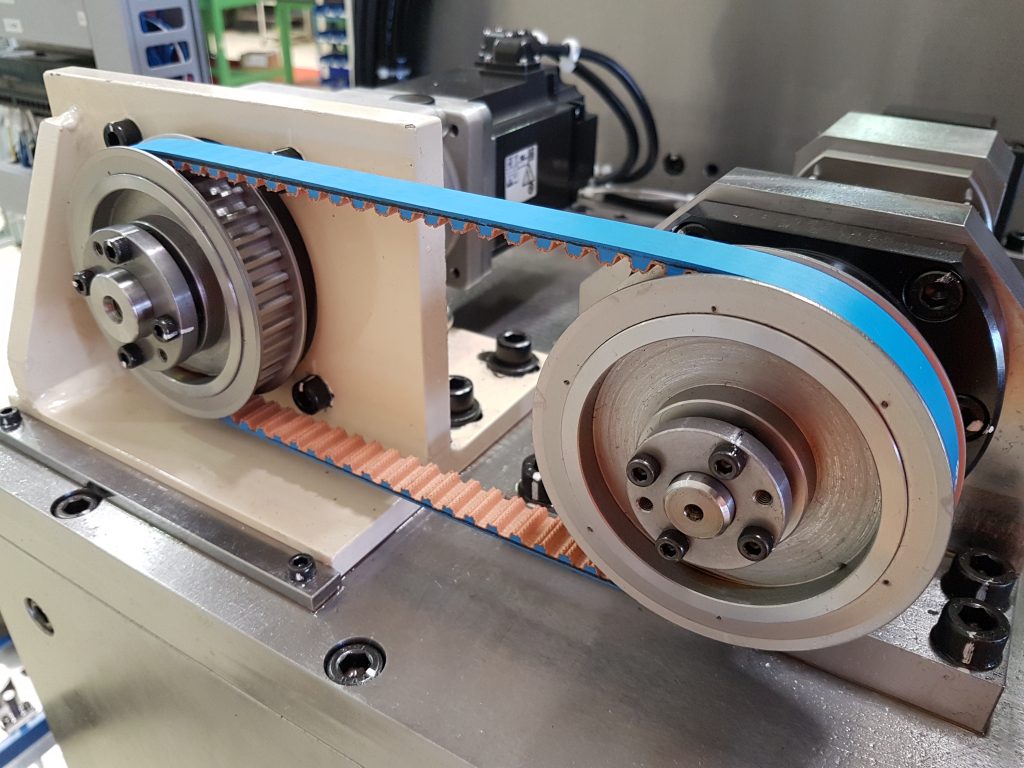

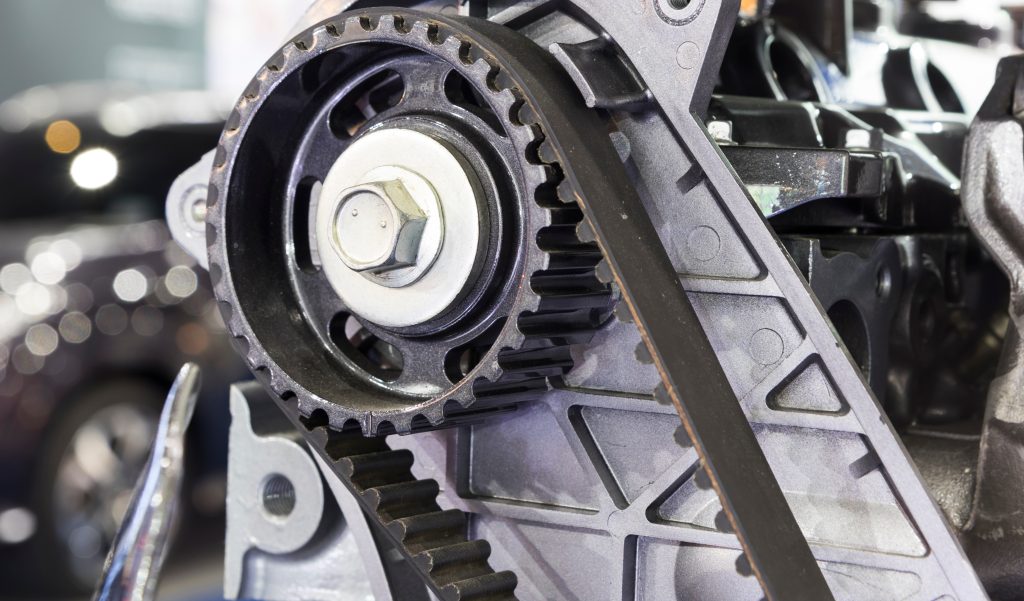

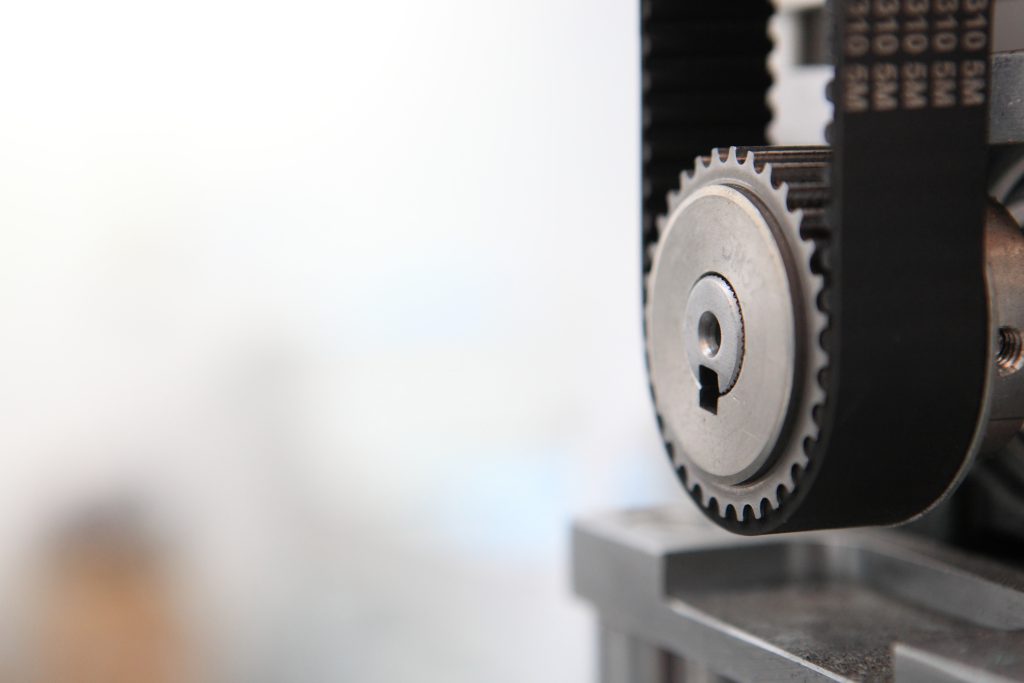

Timing belts are drive belts with teeth on the inner surface that provide precise torque transmission without slippage. They are used in mechanisms where synchronization is important, such as in automobile engines, machine tools and industrial installations. Such belts are characterized by durability, quiet operation and resistance to wear.

Fill out the feedback form to get expert advice, learn more about our products, or discuss your project.

Our team will contact you shortly to answer your questions and offer the best solution.